Embark on a culinary journey with our comprehensive guide on How to Shape Agnolotti, a Small Filled Pasta. This exploration delves into the art and science behind crafting these delightful parcels of flavor, ensuring every step is clear and approachable.

We will uncover the essential elements of creating perfect agnolotti, from the foundational dough preparation and the selection of crucial tools to mastering the intricate shaping techniques. Discover how to balance the delicate art of filling application with secure sealing methods, ensuring your agnolotti are as beautiful as they are delicious.

Understanding the Basics of Agnolotti Dough

Crafting perfect agnolotti begins with a foundational understanding of its dough. This delicate pasta requires a specific balance of ingredients and a meticulous approach to mixing and kneading to achieve the ideal texture and elasticity. Mastering these initial steps is crucial for successful shaping and a delightful final product.The classic agnolotti dough is surprisingly simple, relying on a few core components to create a tender yet resilient pasta.

This foundation ensures that the dough can be rolled thin enough to be delicate, yet strong enough to hold its delicious filling without tearing.

Fundamental Ingredients for Agnolotti Dough

A traditional agnolotti pasta dough is composed of just a few essential ingredients, each playing a vital role in the final texture and flavor. The quality and proportion of these ingredients directly influence the ease of handling and the final eating experience.

- Flour: Typically, a blend of ’00’ flour and all-purpose flour is used. ’00’ flour is finely milled and low in gluten, contributing to a silky, tender pasta. All-purpose flour provides structure. Some recipes may also incorporate semolina flour for a slightly chewier texture.

- Eggs: Fresh, large eggs are fundamental. They bind the ingredients, add richness, and contribute to the dough’s color and pliability. The ratio of eggs to flour is critical for achieving the correct consistency.

- Water (Optional): In some recipes, a small amount of water may be added, especially if the eggs are very small or the flour is particularly dry. This helps to bring the dough together.

- Salt: A pinch of salt enhances the flavor of the pasta itself, preventing it from tasting bland.

Mixing and Kneading Pasta Dough

The process of mixing and kneading is where the gluten structure of the pasta dough develops, transforming individual ingredients into a cohesive and elastic mass. This step requires patience and a feel for the dough’s consistency.The initial mixing combines the dry and wet ingredients, forming a shaggy dough. This is followed by a period of kneading, where the dough is worked repeatedly to strengthen the gluten strands.

Proper kneading results in a smooth, pliable dough that springs back when gently pressed. Over-kneading can lead to tough pasta, while under-kneading will make it difficult to roll and prone to tearing. A good indicator of sufficient kneading is when the dough becomes smooth, elastic, and no longer sticky.

“Kneading is the heart of pasta making; it develops the structure that holds the filling and gives the pasta its delightful chew.”

Resting the Dough

Allowing the pasta dough to rest is a non-negotiable step that significantly impacts its workability and final texture. This period of dormancy is crucial for several reasons.During resting, the gluten strands that have been developed during kneading relax. This relaxation makes the dough much easier to roll out thinly without resistance or snapping back. Additionally, the hydration within the dough becomes more uniform, leading to a smoother and more consistent texture.

A well-rested dough is less likely to tear when being shaped into agnolotti. It is recommended to rest the dough for at least 30 minutes, and up to an hour, at room temperature, or for longer periods in the refrigerator, ensuring it is brought back to room temperature before rolling.

Rolling Out Pasta Dough

The ideal thickness for agnolotti dough is a delicate balance; it needs to be thin enough to be elegant and tender, yet sturdy enough to enclose the filling securely. This is typically achieved through a pasta machine, though a rolling pin can also be used with practice.When using a pasta machine, begin with the widest setting and gradually decrease the thickness setting with each pass, folding the dough as needed.

For agnolotti, the dough should be rolled to a thickness where you can almost see your hand through it when held up to the light. This usually corresponds to the second to last or last setting on most standard pasta machines. If rolling by hand, aim for a thickness of approximately 1-2 millimeters. The surface of the rolled dough should be smooth and free of any rough patches that could lead to tearing.

Essential Tools and Equipment for Shaping Agnolotti

Crafting beautiful and perfectly sealed agnolotti requires a thoughtful selection of tools that enhance both efficiency and precision. While the dough itself is fundamental, the right equipment can transform the shaping process from a potentially tedious task into an enjoyable and rewarding experience. These tools are designed to help you achieve consistent results, ensuring each agnolotti is a miniature masterpiece ready for its culinary journey.The process of shaping agnolotti benefits greatly from specific tools that facilitate the rolling of dough to the correct thickness, the precise cutting of pasta sheets, and the secure sealing of the filling.

Investing in a few key pieces of equipment can significantly elevate the quality and appearance of your homemade agnolotti, making the effort truly worthwhile.

Pasta Machines and Rolling by Hand

The choice between using a pasta machine and rolling dough by hand significantly impacts the ease and consistency of achieving the ideal thickness for agnolotti. A pasta machine offers unparalleled control and uniformity, which is crucial for delicate filled pasta.Rolling by hand, while traditional and potentially meditative, requires considerable skill and physical effort to achieve consistently thin and even pasta sheets.

This can be challenging, especially when preparing a large batch of agnolotti, and variations in thickness can affect both the cooking time and the final texture.Pasta machines, on the other hand, allow for gradual thinning of the dough through a series of rollers. Most machines come with adjustable settings, enabling you to select the precise thickness required for agnolotti, typically between settings 6 and 8 on a standard machine, which is about 1-1.5mm thick.

This consistency ensures that the pasta cooks evenly and the filling is well-contained without the dough becoming too thick or too fragile. The ability to quickly produce long, uniform sheets also speeds up the production process considerably.

Cutters and Bench Scrapers

Once the pasta sheets are rolled to the desired thickness, specific cutting tools are essential for preparing them for filling and shaping. Bench scrapers play a dual role in this stage.A bench scraper is a flat, rigid piece of metal or plastic with a handle. It is invaluable for:

- Lifting and transferring delicate pasta sheets without tearing them.

- Cleaning the work surface of stray flour and dough scraps.

- Helping to smooth and shape the pasta dough as it is being worked.

- Acting as a guide for straight cuts when dividing larger pasta sheets into manageable portions.

For cutting the pasta sheets into individual agnolotti portions, various cutters can be employed. A sharp knife or a fluted pastry wheel is commonly used to cut the pasta into rectangles or squares, depending on the desired agnolotti shape. The fluted edge of a pastry wheel not only cuts the pasta but also creates a decorative edge, which can add to the visual appeal of the finished product.

For more uniform shapes, particularly when creating rows of agnolotti, a pizza cutter can also be an effective tool.

Ravioli Stamps and Crimping Tools

The sealing of agnolotti is a critical step to ensure the filling remains intact during cooking. While the classic method involves folding and pressing, specialized tools can greatly enhance this process, providing both security and aesthetic appeal.Ravioli stamps and crimping tools are designed to press and seal the edges of filled pasta. These tools come in various forms:

- Round Ravioli Stamps: These are typically metal or plastic discs with a fluted edge, used to cut and seal circular pockets of pasta.

- Square or Rectangular Ravioli Stamps: Similar to round stamps, these create larger, often more traditional shapes for filled pasta. They are ideal for agnolotti that are typically folded into a square or rectangular shape before being joined.

- Crimping Tools (Fork or Pastry Tongs): A simple dinner fork can be used to press down the edges of the pasta, creating a ridged seal. Specialized pastry tongs are also available, which are designed to grip and press the edges, offering a more ergonomic and consistent crimp.

The primary function of these tools is to create a strong, airtight seal, preventing any leakage of the filling. The fluted edges also impart a decorative finish, making the agnolotti visually appealing. When using a ravioli stamp, you typically place a dollop of filling onto one pasta sheet, cover it with another, and then press the stamp firmly over the filling to cut and seal.

For hand-crimping, after placing the filling and folding the pasta, you would use a fork or crimping tool to press along the entire seam.

Optimized Workstation Setup for Agnolotti Production

An efficient workstation is paramount for a smooth and enjoyable agnolotti-making experience, especially when preparing larger quantities. A well-organized setup minimizes wasted movement and reduces the likelihood of errors or dough drying out.A recommended workstation setup includes the following elements, arranged logically for workflow:

- Flour and Tools Area: A clean, ample surface area dusted lightly with flour. This is where the pasta sheets will be placed, cut, and filled. Keep a small bowl of flour readily accessible for dusting.

- Pasta Machine Station: Position the pasta machine at one end of the workstation, allowing easy access for feeding the dough and collecting the rolled sheets. Ensure it is stable and secure.

- Cutting and Filling Zone: Adjacent to the pasta machine, this area is for cutting the pasta sheets into desired sizes and placing the filling. Have your filling in a bowl or piping bag within easy reach.

- Sealing and Shaping Tools: Keep your ravioli stamps, crimping tools, and bench scraper close at hand in this zone.

- Drying Rack (Optional but Recommended): If making a large batch, a pasta drying rack can be useful for temporarily holding formed agnolotti, preventing them from sticking together while you continue shaping.

- Completed Agnolotti Area: A designated space, perhaps a lightly floured baking sheet or tray, to place the finished agnolotti as they are completed.

The key principle is to arrange these components in a sequence that mirrors the agnolotti-making process: roll, cut, fill, seal, and place. This minimizes the need to reach or move excessively, allowing for a focused and efficient production line. For example, after rolling a sheet of pasta, you would immediately move it to the cutting and filling zone, then to the sealing area, and finally to the designated spot for finished pasta.

This systematic approach not only saves time but also helps maintain the quality and integrity of the delicate pasta dough.

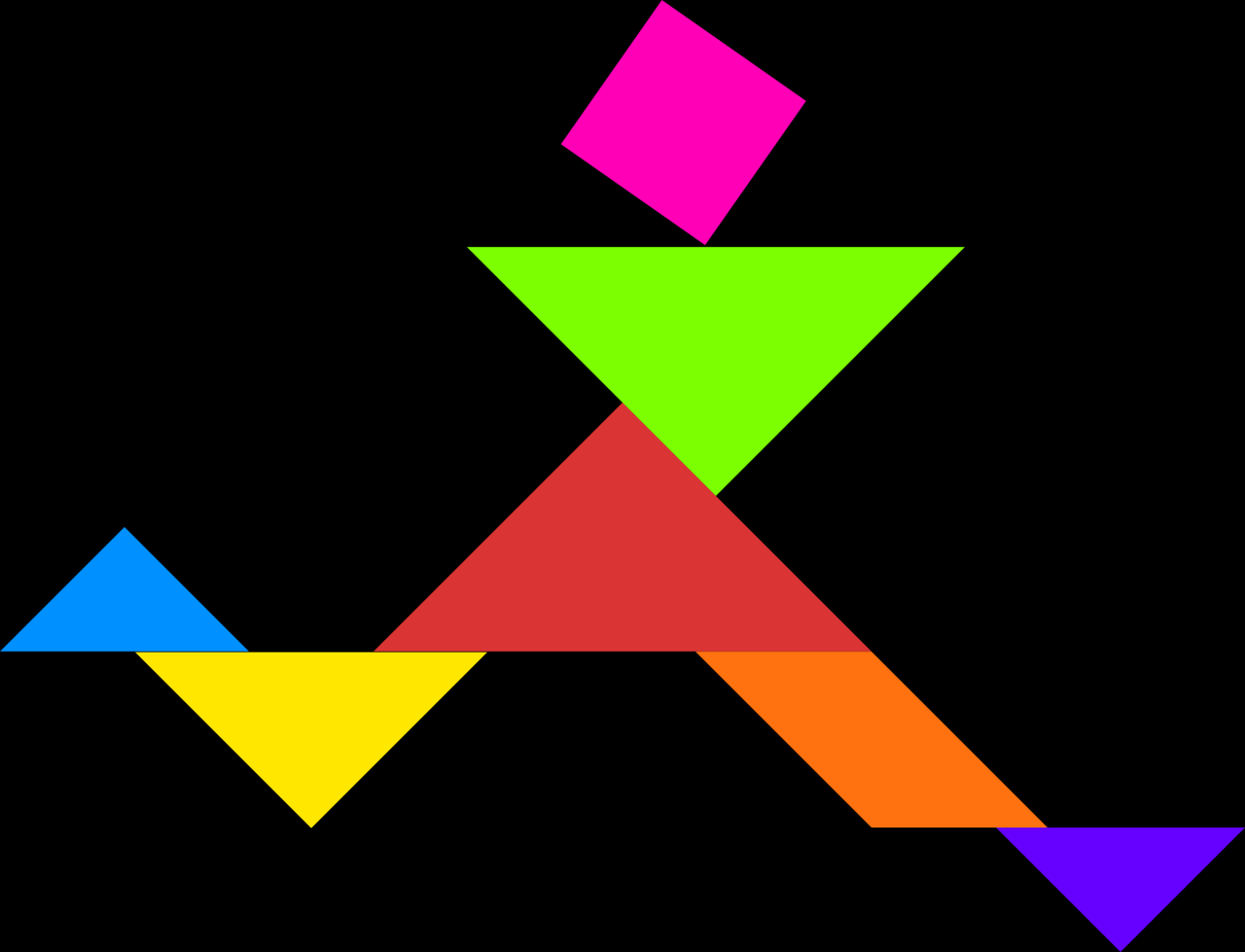

Classic Agnolotti Shaping Techniques

Having prepared your dough and gathered your tools, you’re ready to delve into the art of shaping agnolotti. This section focuses on the traditional and most iconic method: agnolotti del plin. This technique, characterized by its small size and distinctive pinch, is a testament to the finesse and precision of Italian pasta making. Understanding this method will not only allow you to create authentic agnolotti but also appreciate the nuances that differentiate them from other filled pastas.The “plin” technique, meaning “pinch” in the Piedmontese dialect, is renowned for its delicate and labor-intensive approach.

It involves carefully folding and sealing the pasta to create small, bite-sized parcels that are perfect for showcasing rich fillings. This method emphasizes a tight seal to prevent any of the precious filling from escaping during cooking, ensuring each agnolotto is a complete and flavorful experience.

The Agnolotti del Plin Technique

The agnolotti del plin is a small, pinched pasta shape originating from the Piedmont region of Italy. Its defining characteristic is its size and the way it is sealed, often with a thumb press that creates a small, ridged edge. This technique is particularly well-suited for smaller, more intensely flavored fillings.Here’s a step-by-step guide to forming agnolotti del plin:

- Begin with your rolled pasta sheet, ensuring it is of an even thickness, typically around 1-2 millimeters.

- Place small, evenly spaced portions of your chosen filling along one half of the pasta sheet. The amount of filling will depend on the size you desire for your agnolotti, but aim for consistency.

- Gently fold the other half of the pasta sheet over the filling, covering it completely.

- Using your fingertips, press down around each mound of filling to expel any air and to begin to define the individual agnolotti.

- With a fluted pastry wheel or a sharp knife, cut between the filled portions to separate them into individual squares or rectangles.

- To create the characteristic “plin” shape, hold each pasta square with the filling on one side. Gently pinch the two edges of the pasta together, starting from one end and working your way to the other, creating a sealed pocket. A common method involves using your thumb to press and seal the pasta, creating a small, raised ridge.

- You can then further refine the shape by gently pressing the corners inward, creating a slightly curved or elongated shape, depending on your preference.

Comparison with Other Filled Pasta Shapes

While agnolotti del plin shares the fundamental concept of a filled pasta with shapes like ravioli, its execution and final form are distinct. Understanding these differences highlights the unique appeal of agnolotti.

| Feature | Agnolotti del Plin | Ravioli |

|---|---|---|

| Size | Typically smaller, bite-sized (around 2-3 cm) | Varies greatly, often larger than agnolotti |

| Shape | Small, pinched, often slightly curved or rectangular with a distinct sealed edge | Generally square, rectangular, or round, with edges sealed firmly |

| Sealing Method | Characterized by a “pinch” or thumb press, creating a ridged seal | Edges are typically pressed together and sealed with a fork or fingers |

| Dough Thickness | Often uses thinner dough to maintain delicacy | Can accommodate slightly thicker dough |

| Filling Application | Small, concentrated portions | Larger portions, allowing for a wider variety of textures |

Efficient Batch Formation

To streamline the process of shaping a large batch of agnolotti, a systematic approach is key. Organizing your workspace and actions can significantly improve efficiency and consistency.To efficiently form a batch of agnolotti, consider the following sequence of actions:

- Prepare Your Workspace: Ensure you have ample clean surface area, with your pasta sheets, filling, and tools within easy reach. Have a lightly floured tray or baking sheet ready to place the finished agnolotti.

- Consistent Filling: Use a piping bag or a small spoon to place uniform amounts of filling on the pasta sheet. This ensures that each agnolotto will have a similar filling-to-dough ratio.

- Work in Sections: Instead of trying to fill and shape an entire sheet at once, work on one section of the pasta sheet at a time. This prevents the dough from drying out.

- Double-Check Seals: As you fold and pinch, take a moment to ensure each agnolotto is well-sealed. A quick press with your fingertip can prevent any accidental openings.

- Cutting and Separating: Use a sharp pastry wheel or knife to cut cleanly between the agnolotti. A quick, decisive cut will prevent the dough from sticking or tearing.

- Consistent Pinching: Develop a rhythm for the pinching motion. Consistent pressure and movement will lead to uniformly shaped agnolotti.

- Resting Space: As you form them, place the agnolotti in a single layer on your prepared tray, ensuring they do not touch each other to prevent sticking.

Filling Preparation and Application for Agnolotti

The heart of any agnolotti lies in its filling, and preparing it correctly is paramount to achieving beautifully shaped, delicious pasta parcels. A well-executed filling not only enhances the flavor but also ensures the integrity of the agnolotti during shaping and cooking. The consistency of your filling will directly impact how easily it spreads, how well it adheres to the pasta, and ultimately, whether your agnolotti will hold their shape without bursting.Understanding the ideal consistency for your agnolotti filling is crucial for successful shaping.

A filling that is too wet can make the pasta sheet soggy and difficult to handle, leading to tears and leaks. Conversely, a filling that is too dry might crumble and fail to spread evenly, resulting in unevenly filled pasta or gaps. The goal is a filling that is cohesive, spreadable, and holds its form without being overly stiff.

Common Filling Ingredients and Flavor Profiles

Traditional agnolotti fillings often draw from regional Italian culinary heritage, showcasing a harmonious blend of flavors and textures. These fillings are typically rich and savory, designed to complement the delicate pasta dough.Common ingredients include:

- Meats: Roasted meats like beef, pork, or veal, often braised or slow-cooked until tender and then finely minced or ground.

- Cheeses: Parmigiano-Reggiano, Grana Padano, ricotta, or sometimes a creamy gorgonzola for a sharper note.

- Vegetables: Spinach, swiss chard, or other greens, blanched and squeezed dry before chopping. Pumpkin or squash, roasted and pureed, offers a sweet and earthy dimension.

- Aromatics: Garlic, onion, and herbs such as parsley, sage, or rosemary, sautéed to release their fragrance.

- Binders: Sometimes an egg or a touch of breadcrumbs are used to help bind the ingredients together.

Flavor profiles vary widely, but often revolve around:

- Savory and Rich: A classic combination of braised meats and aged hard cheeses creates a deep, satisfying flavor.

- Earthy and Sweet: Fillings featuring roasted pumpkin or squash, complemented by sage and a hint of nutmeg, offer a delightful contrast.

- Herbal and Fresh: Combinations of finely chopped greens with ricotta and a touch of lemon zest can provide a lighter, brighter taste.

Optimal Filling Amount

Applying the correct amount of filling is a delicate balance. Too little filling will result in agnolotti that are mostly pasta, lacking in flavor and substance. Too much filling, however, is the primary cause of agnolotti bursting during shaping or cooking. The pasta dough needs enough space to be sealed properly without being stretched too thin or put under excessive pressure.For most agnolotti recipes, the ideal amount of filling is approximately one teaspoon to one tablespoon per agnolotti, depending on the size and desired outcome.

This should be applied in a way that allows for a generous yet manageable portion.

The key is to leave adequate space around the filling for sealing the pasta edges.

Methods for Even Filling Distribution

Achieving an even distribution of filling is essential for consistent agnolotti and to prevent the formation of air pockets, which can lead to uneven cooking and potential bursting. Air pockets can cause areas of the pasta to puff up unevenly, creating weak points.Several methods can be employed to ensure the filling is spread uniformly:

- Piping Bag: For smoother, more homogenous fillings (like pureed vegetables or ricotta mixtures), a piping bag with a medium-sized tip is an excellent tool. This allows for precise placement and an even layer of filling across the pasta sheet.

- Spoon or Spatula: For chunkier fillings, a small spoon or a dedicated offset spatula can be used. Gently spread the filling in a consistent layer, ensuring it covers the intended area without overfilling or leaving gaps.

- Gentle Tamping: After applying the filling, a light, gentle tamp with the back of a spoon or a clean fingertip can help to settle the filling and remove any immediate air pockets. This should be done carefully to avoid pressing the filling through the pasta.

- Visual Inspection: Before folding the pasta, take a moment to visually inspect the filling. Ensure it forms a continuous, even layer across the pasta sheet, with no significant peaks or valleys, and no areas that are too thinly spread.

Sealing and Finishing Agnolotti

Ensuring a perfect seal is paramount to the success of your agnolotti. A well-sealed pasta parcel not only prevents the delicious filling from escaping during the cooking process but also contributes to the aesthetic appeal of the final dish. This section will guide you through the essential techniques for achieving a secure closure and a polished finish.

Ensuring a Secure Seal

A robust seal prevents your carefully prepared filling from escaping into the cooking water, ensuring each agnolotto remains intact and flavorful. This is achieved through a combination of proper dough hydration, sufficient filling application, and careful manipulation of the pasta edges.

To achieve a secure seal, consider the following:

- Dough Consistency: Ensure your agnolotti dough is neither too dry nor too wet. A slightly tacky dough will adhere to itself more effectively. If the dough feels too dry, a light misting of water can help.

- Filling Placement: Avoid overfilling the agnolotti. Too much filling can push against the dough edges, making it difficult to seal properly. Leave adequate space around the filling for the dough to fold over.

- Edge Moistening: Lightly moisten the edges of the pasta where the seal will be made. A fingertip dipped in water is usually sufficient. This creates a sticky surface that encourages the dough to bond.

- Pressing the Seal: After folding the dough, press firmly along the entire seam. Use your fingertips to work out any air pockets and ensure complete adhesion. You can also use the tines of a fork for added security and a decorative edge, though this is less traditional for some agnolotti styles.

- Double Sealing: For extra peace of mind, especially with delicate fillings or thinner dough, consider a double seal. This involves pressing the initial seal and then folding the edge over once more and pressing again.

Trimming Excess Dough

Neat, uniform agnolotti not only look more appealing but also cook more evenly. Trimming away excess dough after sealing creates a clean edge and a consistent shape.

The process of trimming excess dough involves precision and the right tools:

- Tool Selection: A sharp knife, a pizza cutter, or a fluted pastry wheel are ideal for trimming. A sharp tool will create a clean cut, preventing the dough from tearing or stretching.

- Cutting Technique: When trimming, aim for a straight and consistent cut along the sealed edge. For rectangular or square agnolotti, this means cutting parallel lines. For more rounded shapes, follow the natural curve of the folded dough.

- Uniformity: Strive for consistency in the size and shape of your agnolotti. This ensures they cook at the same rate, preventing some from becoming overcooked while others are still underdone.

- Dough Remnants: Any trimmed dough scraps can often be re-kneaded and re-rolled, provided they haven’t become too dry or tough.

Handling Shaped Agnolotti Before Cooking

Once shaped and trimmed, agnolotti require careful handling to prevent them from sticking to each other or to the work surface before they reach the boiling water.

Proper pre-cooking handling preserves the integrity of your agnolotti:

- Flour or Semolina Dusting: Generously dust a clean, dry surface, such as a baking sheet or a clean kitchen towel, with all-purpose flour or fine semolina. This acts as a barrier, preventing the pasta from sticking.

- Arrangement: Place the shaped agnolotti on the dusted surface in a single layer, ensuring they do not touch each other. If they are packed too closely, they can stick together.

- Gentle Movement: When moving the agnolotti, do so gently to avoid deforming their shape or breaking the seal.

- Refrigeration (Optional): For best results, especially if making a large batch, it is often recommended to chill the shaped agnolotti for at least 30 minutes. This allows the dough to firm up, which further helps them maintain their shape during cooking and can even improve the texture. A lightly dusted baking sheet is ideal for this chilling step.

Visual Inspection of Shaped Agnolotti

A final visual inspection is a crucial step to catch any potential issues before the agnolotti are cooked. This proactive approach can save you from encountering problems during the cooking process.

Conducting a thorough visual inspection involves looking for specific indicators:

- Seal Integrity: Carefully examine each agnolotto’s seam. Look for any gaps, thin spots, or areas where the dough edges haven’t fully bonded. A slight ridge along the seal is desirable, indicating a good press.

- Air Pockets: Gently feel the agnolotti. If you detect any firm, trapped air pockets within the pasta, try to gently press them out towards the edges before sealing completely. Air pockets can lead to bursting during cooking.

- Dough Thickness: Ensure the dough thickness is relatively uniform across all agnolotti. Inconsistent thickness can lead to uneven cooking.

- Shape Consistency: While perfect uniformity isn’t always necessary, a general consistency in size and shape is a good sign that they will cook evenly.

- Tears or Thin Spots: Look for any tears or excessively thin areas in the pasta, particularly around the edges or where the filling is close to the surface. These areas are prone to breaking.

A well-sealed agnolotto is a testament to careful preparation, ensuring every bite is a perfect parcel of flavor.

Variations in Agnolotti Shapes and Styles

Beyond the classic forms, agnolotti boasts a rich tapestry of regional variations, each with its unique shape, filling, and culinary tradition. These differences are not merely aesthetic; they often reflect local ingredients, historical influences, and the desired mouthfeel and sauce pairing. Exploring these variations allows for a deeper appreciation of this versatile filled pasta.The art of shaping agnolotti is wonderfully adaptable, allowing for creativity in size and form.

Whether you prefer petite morsels or more substantial pockets of flavor, the fundamental techniques can be adjusted to suit your preference and the intended dish.

Regional Agnolotti Variations and Fillings

Different regions in Italy have developed their own distinct styles of agnolotti, often tied to specific local ingredients and culinary customs. These variations showcase the adaptability of the agnolotti concept.

- Agnolotti del Plin (Piedmont): These are arguably the most famous. Characterized by their small size and pinched “pinch” (plin) shape, they are traditionally filled with a rich roast meat mixture, often including beef, pork, and rabbit, seasoned with herbs and sometimes a touch of Parmigiano Reggiano. They are typically served with a simple meat broth or a butter and sage sauce.

- Agnolotti Veronesi (Veneto): Larger than del Plin, these agnolotti often feature a filling of roasted meats, including beef, pork, and sometimes chicken, combined with breadcrumbs, herbs, and a hint of garlic. They are frequently served with a rich meat sauce or a tomato-based ragù.

- Agnolotti di Carne (Lombardy): While “agnolotti di carne” can refer to any meat-filled agnolotti, in Lombardy, it often implies a filling of mixed roasted meats, similar to Piedmontese versions but sometimes incorporating different herbs or spices based on local availability.

- Agnolotti di Pesce (Coastal Regions): In areas near the sea, agnolotti can be filled with various types of fish and shellfish, such as shrimp, crab, or white fish, often mixed with herbs, lemon zest, and breadcrumbs. These are typically served with lighter sauces, such as a white wine sauce or a light tomato broth.

Adapting Shaping for Size

The process of shaping agnolotti can be easily modified to create larger or smaller versions, each offering a different dining experience. The core principles of dough handling, filling application, and sealing remain consistent, with adjustments primarily in portion size and folding techniques.For larger agnolotti, you might opt for slightly thicker dough to ensure structural integrity and a more substantial bite.

The filling portions will naturally be larger as well. When folding, ensure a secure seal to prevent any leakage during cooking. This size is well-suited for heartier sauces and ragùs.Conversely, smaller agnolotti, often referred to as “agnolottini,” require a lighter touch and thinner dough. The filling portions are minuscule, demanding precision. The folding might be simpler, perhaps a single fold over the filling, creating delicate, bite-sized parcels.

These are ideal for lighter broths or as an accompaniment to other dishes.

Visual Appeal and Textural Differences

The shape of agnolotti significantly influences its visual presentation and the textural experience when eaten. The surface area, the way the dough folds, and the overall form all contribute to how the pasta interacts with sauces and the palate.The pinched shape of agnolotti del plin creates small pockets that hold sauce beautifully, offering a delightful burst of flavor with each bite.

The slightly ruffled edges add a rustic charm. Larger agnolotti, especially those with a more squared or rectangular form, present a bolder visual and a more substantial chew. The flatter surfaces allow for sauces to coat them evenly, while the thicker dough provides a satisfying resistance. Delicate, small agnolottini offer an elegant appearance and a lighter mouthfeel, perfect for delicate broths or as a refined appetizer.

Creative Agnolotti Filling and Shape Pairings

Experimenting with different fillings and shapes can lead to exciting and delicious agnolotti creations. The key is to consider how the filling’s texture and flavor will complement the pasta’s form and the chosen sauce.Here is a list of potential filling and shape pairings to inspire your culinary creativity:

| Shape/Style | Potential Filling | Ideal Sauce Pairing | Notes |

|---|---|---|---|

| Agnolotti del Plin (Small, Pinched) | Braised Veal and Pork Ragu | Butter and Sage, Meat Broth | The small size and pinched shape are perfect for concentrating flavor. |

| Rectangular Agnolotti (Medium to Large) | Ricotta, Spinach, and Lemon Zest | Brown Butter with Toasted Walnuts, Light Cream Sauce | A larger surface area allows for a more even distribution of the creamy filling. |

| Half-Moon Agnolotti (Medium) | Butternut Squash and Amaretti Crumble | Brown Butter with Crispy Sage, Light Parmesan Sauce | The curved shape cradles the sweet and slightly crunchy filling. |

| Square Agnolotti (Medium) | Mushroom Duxelles with Thyme | Porcini Mushroom Cream Sauce, Truffle Butter | A classic shape that holds earthy, rich fillings well. |

| Agnolottini (Tiny, often folded simply) | Smoked Salmon and Dill | Lemon-Dill Cream Sauce, Light White Wine Broth | Delicate size for a refined appetizer or a light pasta course. |

| Scallop-Edge Agnolotti (Medium) | Prosciutto and Fontina Cheese | Light Tomato Sauce with Basil, Garlic-Infused Olive Oil | The decorative edge adds visual appeal to a savory filling. |

Tips for Consistent Agnolotti Production

Achieving consistently shaped and perfectly filled agnolotti, especially when producing in larger batches, requires attention to detail and a systematic approach. This section offers practical advice to help you maintain quality and efficiency throughout the shaping process.

Maintaining Consistent Dough Hydration

The hydration level of your pasta dough is paramount for ease of handling and consistent shaping. A dough that is too wet will be sticky and difficult to manage, while a dough that is too dry will be prone to cracking and tearing.

- Accurate Measurement: Always weigh your flour and liquids precisely using a kitchen scale. Volume measurements can vary significantly based on how flour is scooped and packed.

- Flour Type Variation: Be aware that different brands and types of flour can absorb moisture differently. Adjust liquid amounts slightly if you are using a new flour.

- Resting Time: Allow your dough to rest adequately after kneading. This resting period allows the gluten to relax and the flour to fully absorb the liquid, leading to a more pliable and consistent dough.

- Environmental Factors: Humidity in your kitchen can affect dough hydration. On very humid days, you might need slightly less liquid, and on very dry days, a touch more.

Preventing Dough from Drying Out

Pasta dough is susceptible to drying out, especially when working with it for extended periods. Keeping it properly covered is essential to maintain its pliability.

- Constant Covering: As soon as you finish kneading, wrap the dough tightly in plastic wrap or place it in a sealed container.

- Portioning and Covering: When you are ready to shape, only take out the portion of dough you will be working with immediately. Keep the remaining dough covered.

- Damp Cloth Method: For longer shaping sessions, you can keep rolled-out pasta sheets or shaped agnolotti lightly covered with a slightly damp (not wet) kitchen towel. This creates a humid environment without making the dough sticky.

- Work Surface Management: If working on a floured surface, ensure the flour is lightly dusted and not excessive, as this can also contribute to drying.

Managing a Production Line for Large Quantities

Scaling up agnolotti production involves streamlining the process and assigning tasks efficiently. A well-organized production line ensures that each step is performed consistently and without bottlenecks.

- Task Specialization: Divide the shaping process into distinct tasks and assign them to different individuals if possible. One person could be responsible for rolling out dough, another for cutting, a third for filling, and a fourth for sealing and finishing.

- Workflow Optimization: Arrange your workspace so that the dough moves logically from one station to the next. Minimize unnecessary movement and handling.

- Batch Processing: Work in batches for each stage. For example, roll out several sheets of dough before moving to cutting, then fill a set number before sealing.

- Standardized Tools: Ensure all tools, such as pasta cutters, filling spoons, and sealing tools, are uniform and readily available at each station.

- Quality Control Checkpoints: Implement brief quality checks at key stages, such as after filling and after sealing, to catch any issues early.

Troubleshooting Common Shaping Challenges

Even with the best preparation, you might encounter some common issues during agnolotti shaping. Understanding how to address these will save you time and frustration.

Tearing Dough

Tearing often occurs when the dough is too dry, too thin, or when too much pressure is applied during handling.

- Hydration Adjustment: If the dough consistently tears, it may be too dry. Knead in a tiny amount of water (a teaspoon at a time) until it becomes more pliable.

- Rolling Thickness: Ensure your pasta sheets are rolled to an appropriate thickness. If they are too thin, they will be fragile. Aim for a thickness that allows for easy manipulation without ripping.

- Gentle Handling: Apply gentle but firm pressure when handling the dough, especially when folding or sealing. Avoid dragging or stretching the dough excessively.

- Patching Small Tears: For minor tears, you can often gently pinch them closed or use a small piece of dough to patch the area before proceeding.

Uneven Filling

Uneven filling can lead to agnolotti that are difficult to seal properly or have an unbalanced taste and texture.

- Consistent Portioning: Use a small, standardized spoon or scoop to measure the filling for each agnolotti. This ensures each piece receives the same amount.

- Filling Placement: Place the filling in a consistent location on the dough, typically in the center of where the agnolotti will be formed. Avoid overfilling or placing filling too close to the edges.

- Visual Inspection: Before sealing, quickly visually inspect each filled portion to ensure it looks even and is not overflowing.

- Dough Strength: A well-hydrated and properly rested dough will have enough structure to contain the filling without the filling pushing through or distorting the shape.

Final Thoughts

As we conclude our exploration of How to Shape Agnolotti, a Small Filled Pasta, we trust you are now equipped with the knowledge and inspiration to create these exquisite pasta shapes with confidence. From understanding the dough’s character to mastering the final pinch, each step contributes to a truly rewarding culinary experience. May your kitchen be filled with the aromas of perfectly formed agnolotti, ready to impress and delight.